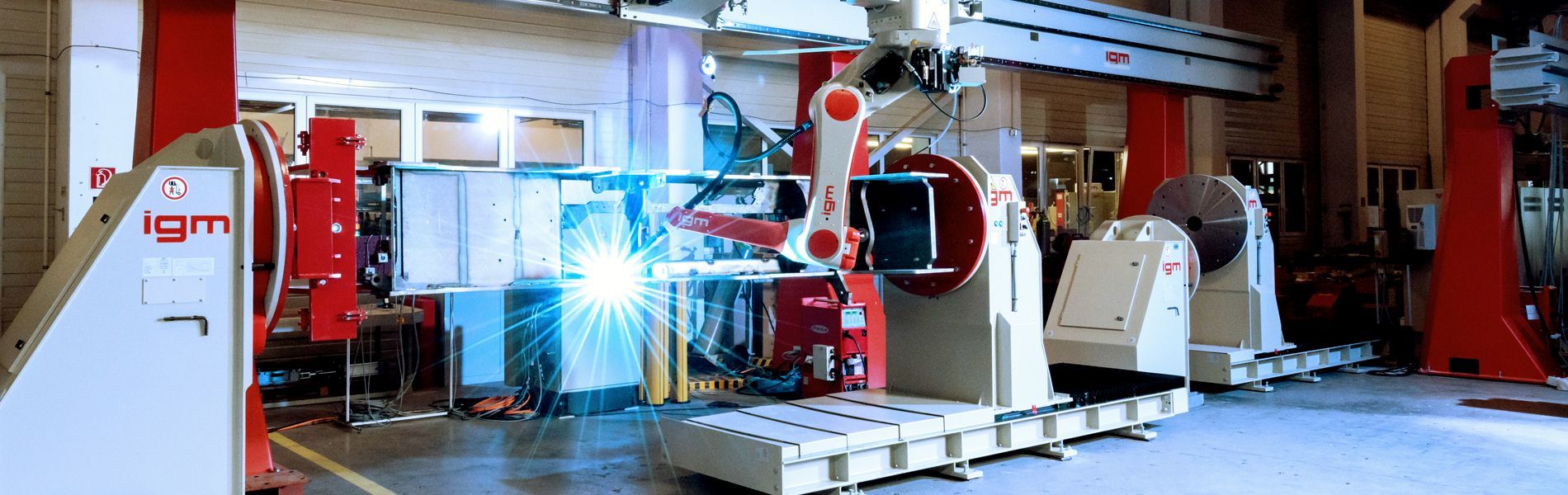

The robotic system is designed for welding components and locomotive frames (frames, cross members, headbeams inside and outside), as well as automated setting of welding parts and trimming of welding lugs. It is a movable large portal (21m length) with 2-station operation; the stations consist of one L-manipulator each with turning, tilting axis and 2m-vertical stroke. The welding robots (2 x RTE 497, KNI-NET) are mounted on a linear movable unit (gantry), with which they perform the change between stations 1 and 2. The large-robot frame welding system comes to a machine weight of 65 tonnes in total.

The robot system can pick up components up to a turning radius for each axis of the manipulator of 3,000 mm and a weight of up to 7 tons including holding device. This corresponds, for example, to a complete locomotive frame with a diagonal dimension of up to six meters; MAG 1-wire and MAG Tandem are used for automated welding, as well as plasma cutting and handling tasks can be covered with this igm large system.