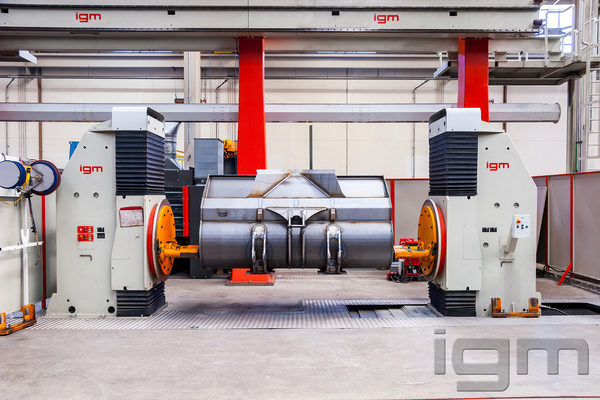

A modular structure of the workpieces is a prerequisite for continuous planning of the production, in this case the creation of the robot welding programmes. Components with the same function must also have the same structure (part families). In order to be able to assemble the robot programmes automatically, the workpiece design must be parametrically structured, i.e. the characteristics of the parts (e.g. main dimensions, number and position of subassemblies) must only be changeable by entering relevant numerical values.

For the modular component production of wheel loader buckets, a software application was created that builds on these prerequisites. The workpieces consist of different modules that are assembled according to the modular principle: Base body, side plates, side cutting edges, bottom cutting edge and teeth are defined in parameters and can be adapted to the respective bucket size with just a few parameters.

For each component, identified by the capacity of the bucket, a file is created in .csv format with a specified structure, which is prepared by the user. The workpiece-relevant data is read from this file and linked to the corresponding robot part programmes stored in the control memory. The assembly of these programme parts at the correct position and in the correct number as well as the subsequent saving as a finished welding programme for this specific component is then carried out automatically by the software.

The software application was created using iSCRIPT and runs under control version K6. The robot welding programs created on the offline programming PC are executable without further verification and are transferred to the robot controller via the network.

The advantage of this method is the uncomplicated, fast generation of robot programmes for different workpieces within a part family. This makes production with batch size 1 possible.