In November 2017, the Beijing Rail Transit Technology and Equipment Group established the company Hebei Jingche Rail Transit Vehicle Equipment Co., Ltd.

In only two years, their company built up a latest state of the art railway vehicle factory, located in Baoding City. The factory covers a construction area of about 470,000m², which is the size of app. 66 FIFA football fields.

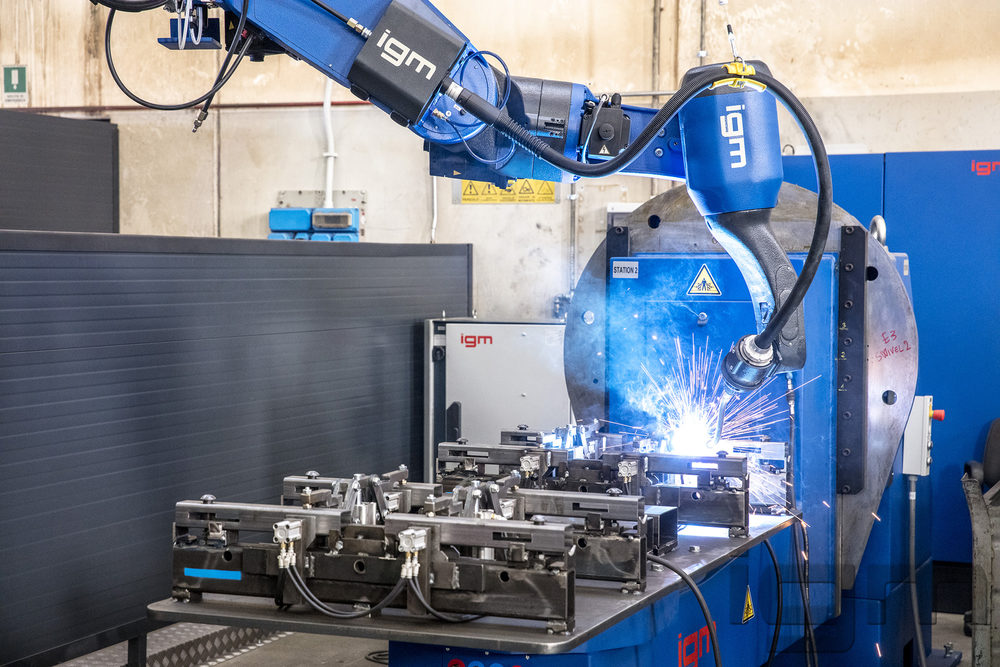

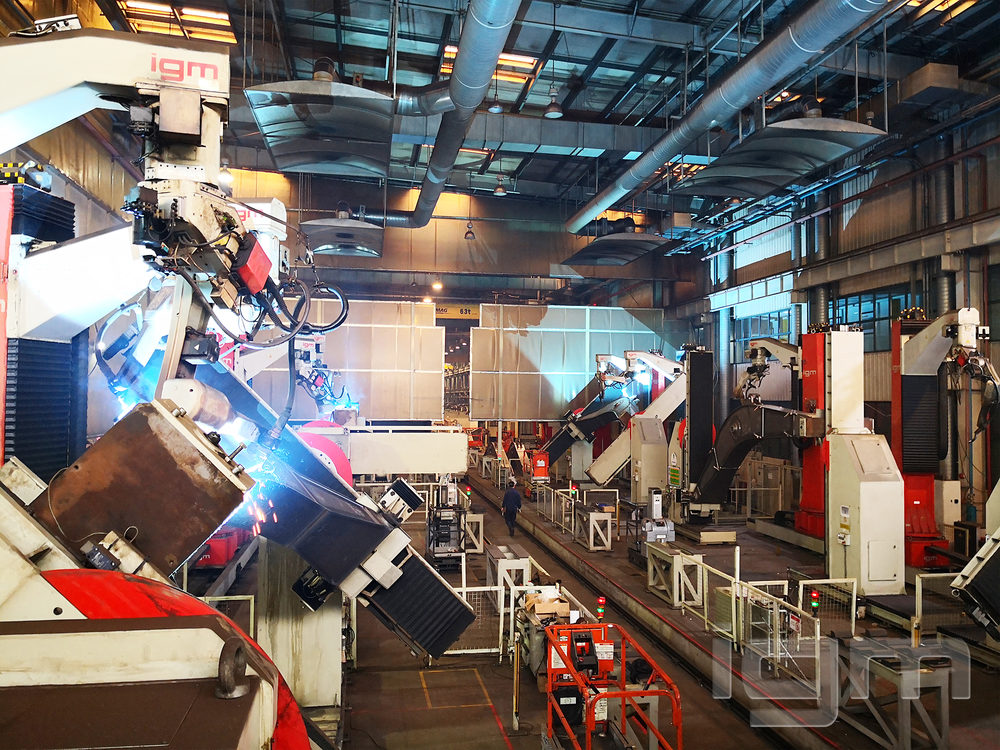

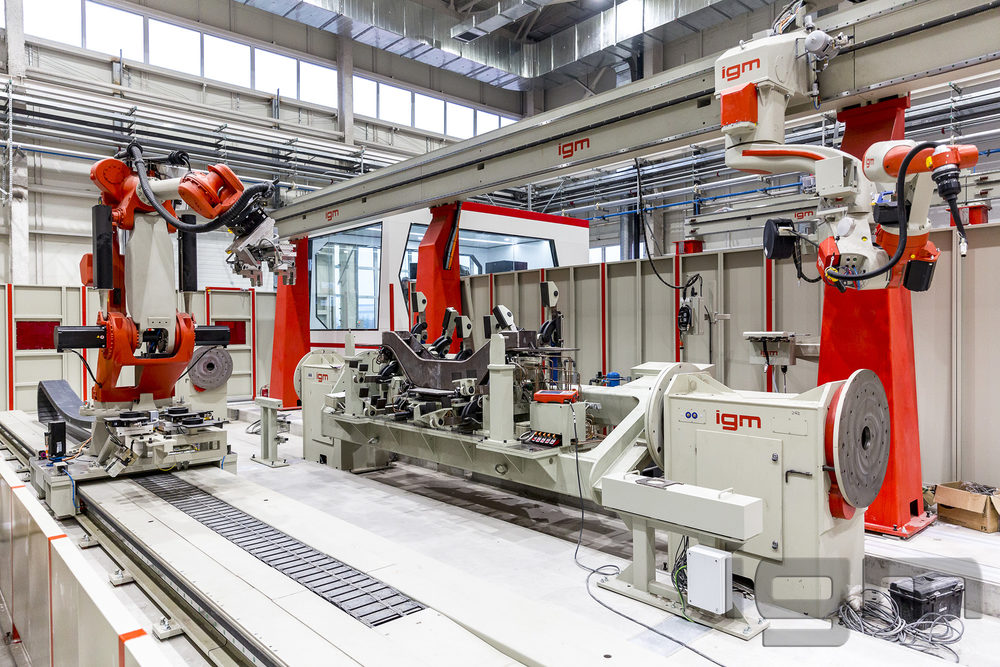

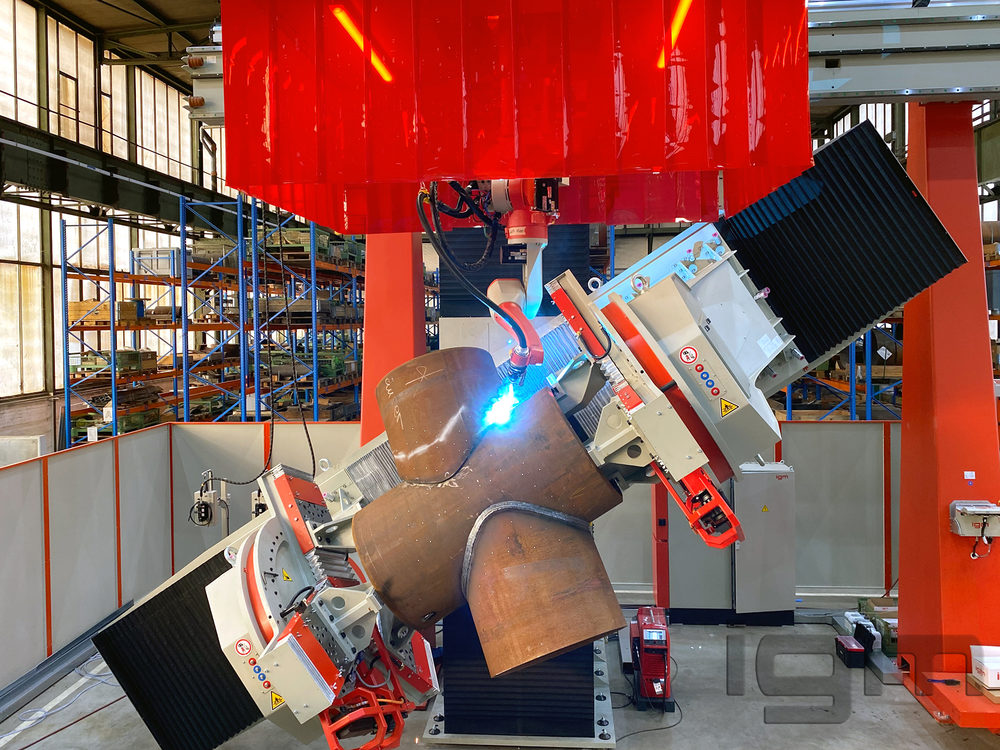

The factory of Hebei Jingche Rail Transit Vehicle Equipment Co., Ltd. is home to an igm bogie FMS with a capacity of 1300 subway bogies per year on a two shift basis.

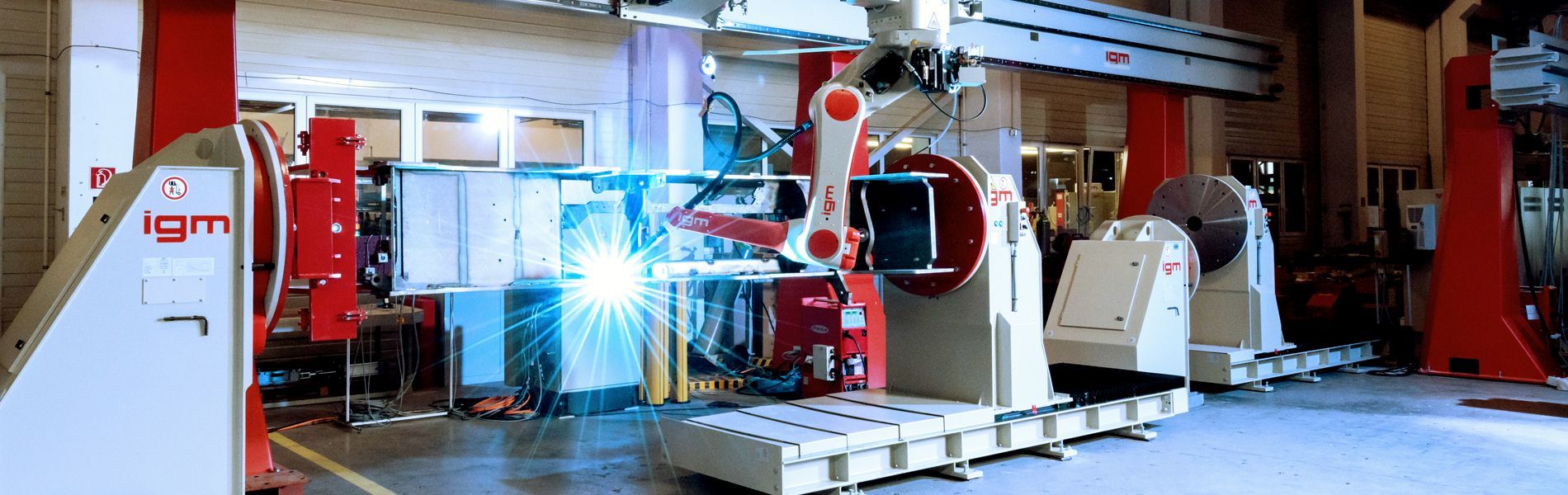

The igm bogie FMS was delivered in 2020 and covers a workshop area of 200 m in length and 25 m in width.

The FMS line was a turn-key project for igm and included design, line layout, development of fixtures, supply of all equipment and commissioning up to hand over to the customer.