The drive is axis-controlled and provided by an AC servo motor with a special gear box and a built-in digital encoder. The turning fixture is perfect for use as an external robot axis. Work piece movement is completely integrated in the robot control system and permits synchronized movement of the work piece during the welding sequence. The programming takes place simple via the teach pendant K6. All necessary control components for manual and automatic operation are integrated in the system.

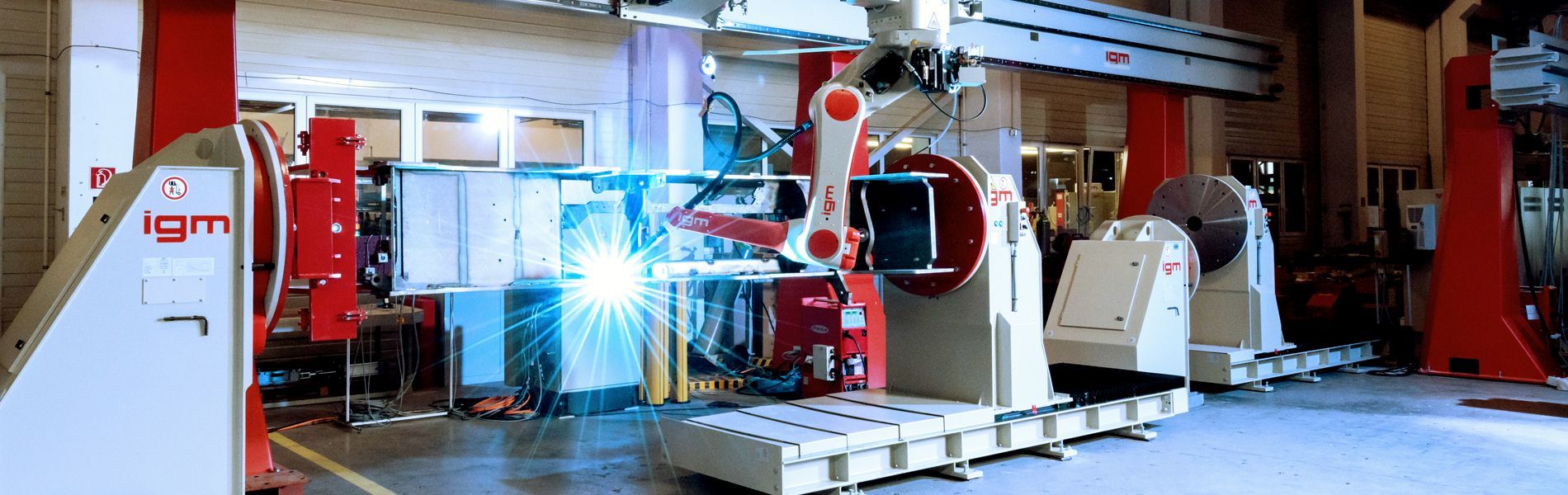

Examples for igm compact systems and complete welding cells

- igm compact systems, type RSX 501, 502, 1001, 1002

- igm compact systems, type RRMK 602, 1002

- igm compact systems, type RRMK/RP2 1002

- igm welding cell, type P2W-10

- igm welding cell, type P2W-20