Basic concepts of flexible manufacturing lines:

- FMS for a single work piece type and a single robot cell

- FMS for several work piece types and a single robot cell

- FMS for a single work piece type and several robot cells

- FMS for several work piece types and several robot cells

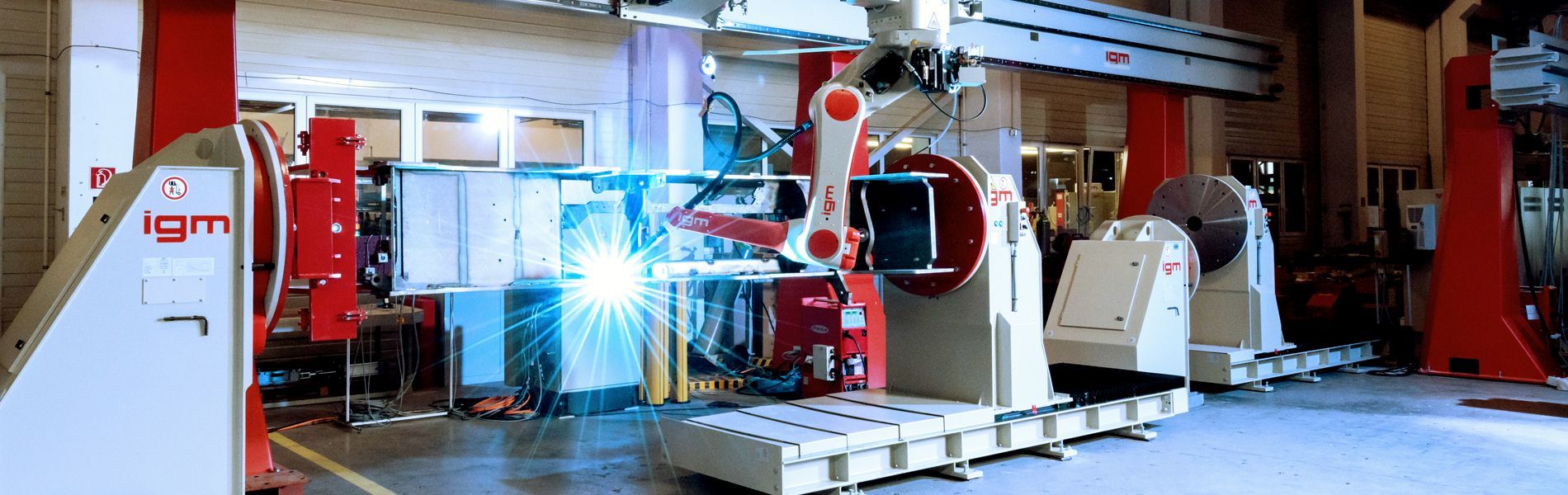

Components of manufacturing lines

- Loading- / unloading stations

- Roller conveyors

- Conveyor carriage

- Buffer stations

- Storage places

- Line control

The whole fabrication line including the robot cells is controlled by one single host computer. Graphic information on the display makes operation and monitoring easy.

Work pieces of totally different shapes and dimensions are handled by specially designed pallets. The innner side of these pallets is designed to clamp the piece parts while the vertical outer side represents the patente clamping device on the positioner's face plate. A built-in sensor monitors the correct clamping.

The conveyor carriage with a satellite carriage and a scissor-table conveys the parts to the robot station, where they are clamped automatically. In each feeding-station the main conveyor is pneumatically indexed with the aim to assure a correct position in relation to the rails of the satellite carriage.