Robonet

igm software for network operation and remote access from an arbitrary PC to the robot control

- Transfer of data to one or more machines

- Remote monitoring of welding and operating data

- Teach pendant display can be viewed on your notebook or PC

ISDES embedded

ISDES EMBEDDED is a weld seam and operating data acquisition system for monitoring, documentation and quality assurance of welding processes, as well as for the evaluation of operating data at partially, or fully automated welding robot systems. The ISDES integrated on the control system offers the possibility to record, monitor and evaluate the parameters decisive for the quality as well as the operationally relevant data.

isdes embedded functions

- directly integrated into the controller > parameterization on the teach pendant

- saved iSDES data can be further processed in Excel

- data processing can be performed on the PC by the user

- automatic allocation of the welding data to the program step

- external sensors integrated into the control cabinet

Smartstep

Smartstep is a software product for igm robot controls which generates interactive step programs with templates via program assembling.

Time and costs for the development of robot programs are essentially important, especially with small batch sizes. Smartstep offers an easy alternative for the assembly of previously created program parts which are prepared and saved in the library. It allows to built an executable robot program with an interactive input window.

Smartstep is mainly used for programming workpieces with a limited amount of repetitive seams.

iPAT (igm program assembly tool)

iPAT (igm Program Assembly Tool) is a very powerful tool which can be used for offline manipulation and the assembling of step programs (template programs). iPAT allows to enter numerically values related to work piece length- and position changes.

The goal of iPAT is to chain template programs after each other to a target program. In doing so, certain step ranges are taken from a template program, will be shifted on the robot or the tracks and will be copied together to a target program by means of a simple input dialog. iPAT can also be used for shifts within one single step program.

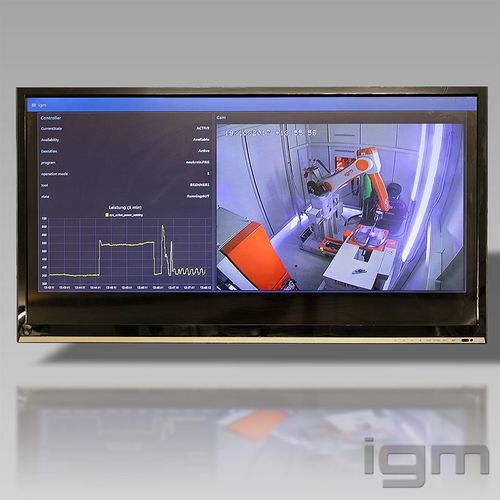

i4i visualisation software

i4i provides a variety of different visualisations and reports of the status of a robot cell. With a PLC interface, it is easy to connect it to the machine. Additionally it allows the integration of various devices such as PC, tablet or smartphone. All robot stations with their status concerning actual runtime and remaining runtime as well as the current program could be shown at a glance.

Furthermore, a live display of each robot cell together with their status reports can be visualized. The work piece tracking tool shows the development of the work piece with all processing steps including its emergency strategies. For the conclusive analysis of the manufacturing process, the SQL data base provides various evaluation possibilities. For example, the availability of the machine and its probability of error as well as the productivity per shift / period of time can be calculated. The user interface is set up during the commissioning of the robot cell and is individually adjusted on the users needs while maintaining all standard functions.