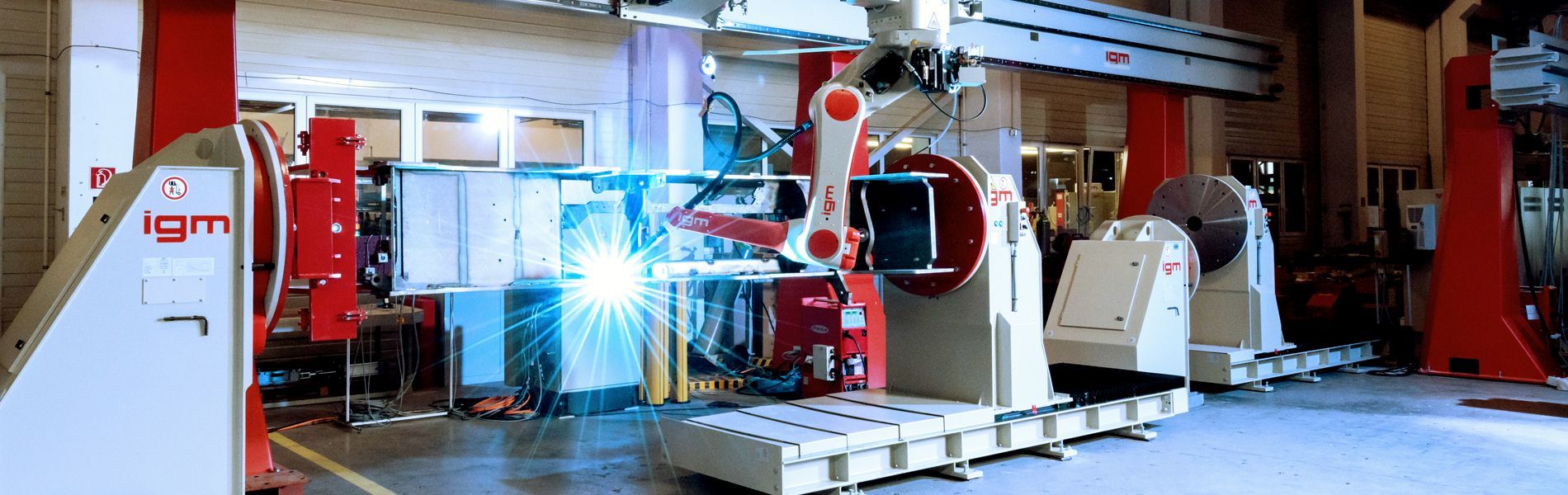

Data

- Robot: RTE 496-S

- Manipulators: 2x 10 tons

- Length of the system: 20 m

- Operation: tandem operation / two shifts

- Components: upper carriage and sliding bars

The system is state-of-the-art. Offline programming keeps the robot system free for production. The camera system, the tandem torch and an automatic wire change ensure the necessary precision and perfection.

After just one year, an extremely positive conclusion can be drawn. The system is working to full capacity. On average you are around 35% faster than with manual welding. The manufacturing costs of the manufactured components can therefore be reduced by approx. 20%.

Article and images © Liebherr-Werk Nenzing GmbH