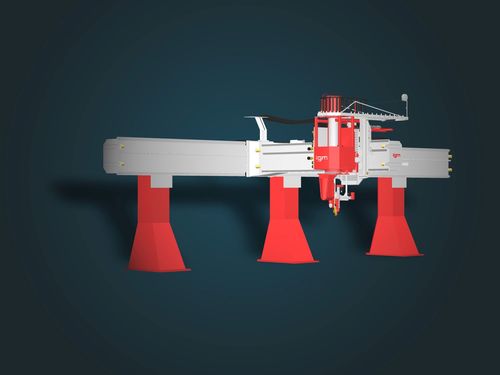

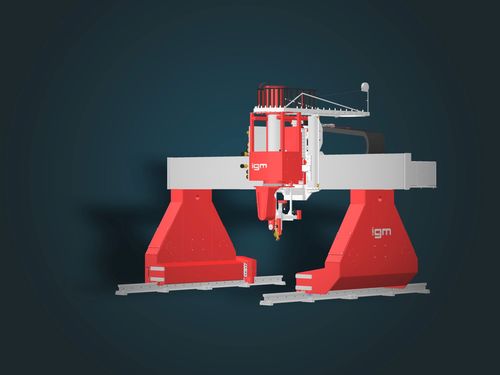

Sensor supported systems can be provided with the igm ibs oxy and plasma cutting machine which are optimized for all mechanical and control requirements for chamfering flat sheet metal. This special characteristic was made possible by the development of a parallelogram-like cutting head, on which the cutting torche, movable in two axes, is mounted. This unit is fitted onto a stable gantry, running on rails, with a cross slide and a vertical slide to take up the parallelogram. The special design of the cutting head allows chamfering of flat sheet metal with any and also alterable chamfer angles on straight or curved cuts.

Automatic sheet thickness measurement

A highly accurate seam joint preparation while maintaining a specified land height or a specified seam volume requires not only the exact tracking of the cutting torch along the contour but also the exact detection of the sheet thickness. For this purpose, the igm bevelling machine can be equipped with an automatic sheet thickness measurement.