LinROB is welding robot components

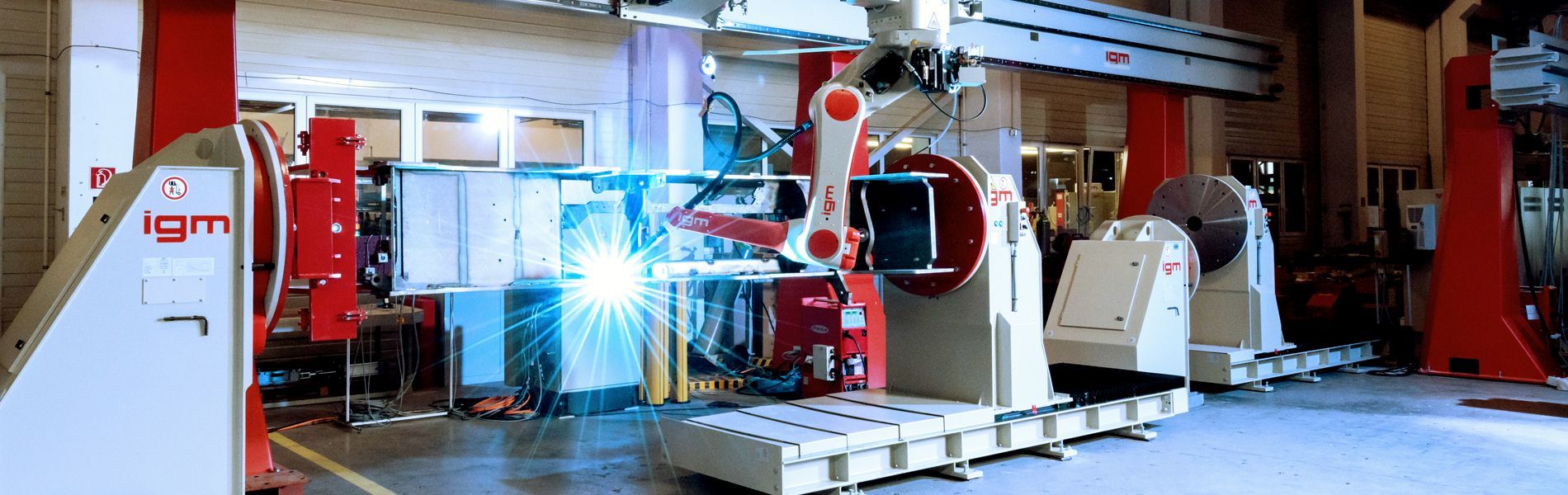

This complete 6-axis robot system LinROB welds in the factory of Moson Acél Kft. in Mosonmagyaróvár, Hungary, besides many other components also the track girders and columns for the igm slide systems. It is already the second igm robot in this company. Moson Acél Kft. is an established sub-supplier for many companies in the steel construction, mechanical engineering and earthmoving sectors.

Flexible system layout for a wide variety of components

The installed LinROB system is built on a floor track with a travel length of 10 m. The possible uses are considerably expanded by an L-manipulator with a 2 t load capacity, which can be combined on a rotary table with a 1-axis rotating device, station load 6 t. In this way, even the longest track girders for the 3-axis robot slide systems can be manufactured.

User benefits through the use of robots

The advantages of welding automation are for the user Moson Acél Kft. in increasing and securing manufacturing quality. The costs are reduced and productivity increased. Not to be neglected is the problem of finding suitable specialists for these demanding welding tasks, which is alleviated by the use of robots. In addition, the use of robots gives them an edge over the competition in terms of manufacturing competence and strengthens their market position.

Technical Data LinROB

- Carriage way floor track: 10,000 mm

- Stroke cantilever arm: 2,500 mm

- Cross carriage way: 3,000 mm

- Rotation range welding head: 570°

- Rotation range arm: 270°

- Rotation range torch: 720°

Rotating Axes for Welding

- Two-part, 3-axis welding arm on an angled bracket with a central lead-through for the hose package

- Hollow shaft wrist axis with welding torch bracket and media feed-through

Features

- slim, linear main axes

- extremely mobile 3-axes-welding head

- telescopic cross slide

- for MIG/MAG-, TIG- and plasma processes

- all variants of linear axis systems and manipulator modules to be integrated

- with teach-in or offline programming