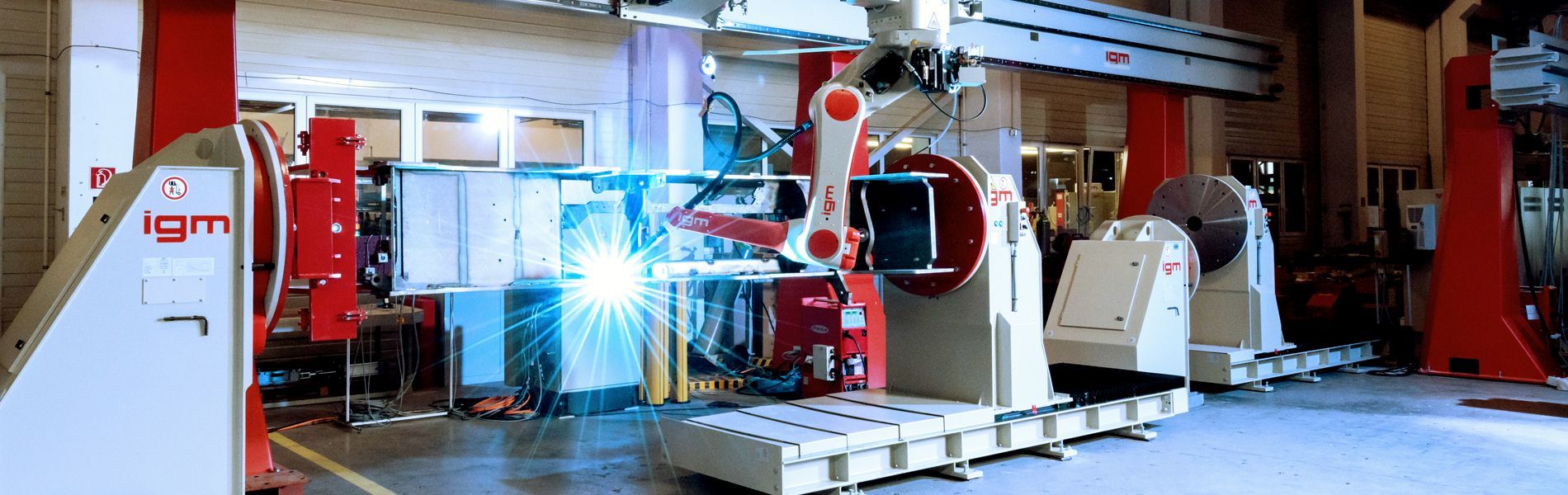

The further technical equipment of this system consists of a preheating torch and an iLS laser sensor in the welding stations, a gripper calibration station and a cleaning station for the magnetic grippers of the handling robot.

The component fixtures for the different workpieces are held on the L-manipulator using a zero-point clamping system. They are automatically changed by the handling robot and stored in a rack system. With this robot system, components for wheel loaders are assembled and welded fully automatically. For this purpose, the raw material is fed into a fully automatic storage system, stored there temporarily and later removed from it by the handling robot.

In order to reduce production time, two identical welding stations are provided, between which the handling robot shuttles and supplies the storage system with material. In a preliminary operation, the components are first assembled and stapled and then fully welded in a subsequent operation. The finished components are then removed from the welding stations by the handling robot and discharged to the transfer station.